wallform

economy panel |

film face plywood |

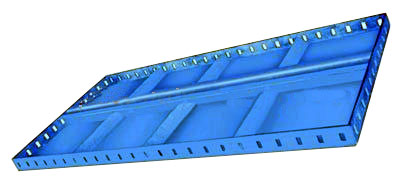

Economy Panels are made using 2.0 mm thick mild steel sheet and angles having holes at regular intervals for joining these panels with other panels sideways and in upward position. It is used for casting floor slabs, beams and walls. It is easy to assemble and dissemble and also has excellent concrete quality. As it is a large steel panel, the sub material costs can be reduced. These panels functions well and reduces risk of damages and loss of material. Due to its large size and weight separate lifting tool is required for moving and installing it at construction site |

Film Faced Plywood is made of poplar or hardwood, the 2 most importand advantage of using this over steel panel is the excellent concrete surface finish and light weight which is very easy to handle by labour on construction site. It comes in sheet form of size 1220 x 2440 mm (thickness -12, 15, 18 and 21mm) |

steel waler |

adjustable column clamp |

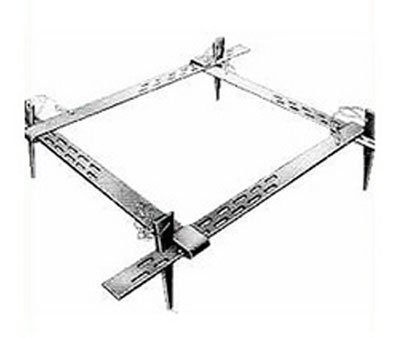

Steel Walers are used to hold the form work in place, due to its robust structure it is capable of resisting the pouring pressure of concrete. These are made out of 'C channels held together by welding angles as shown in the photo. The length can be increased by using splice plates |

Adjustable column clamps are ideally suited for a wide range of column sizes and are usable with both steel and timber shuttering. These clamps have no loose parts. Further interchange ability of arms of different sizes of column clamps makes them extremely versatile. |

soldier |

tie rod assembly |

Soldiers are manufactured using special profile used to connect adjacent steel wall forms to each other, it is highly versatile formwork and support beam, it has exceptional strength and wide variety of application. Available in painted surface finish and adaptable for the contractors to use it for all types of temporary works. Usually the height of the soldiers is one & a half times the height of the wall forms. |

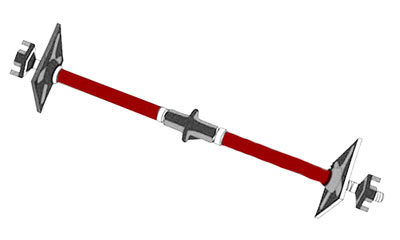

Tie Rod Assembly is used to hold panels on opposite side of the same wall to be casted. |

Floor Form

decking beam |

infill beam |

|||||||||||||||||||||

Decking beams are supportive part which holds the weight of decking materials that is placed on the deck (ie : decking plate & concrete). It is supported on both the ends by adjustable props / standards. These beams are made of 2.0/2.5 mm mild steel sheets bent into a box type and reinforced with lattice, made of steel rods. It is available in various lengths to suit your requirement |

Infill Beams are secondary element placed at right angle on top of decking beams and are supported by it. Decking plates are placed on the top which holds and gives shape to the concrete poured on it to cast the floor |

|||||||||||||||||||||

timber beam |

adjustable telescopic span |

|||||||||||||||||||||

Timber beams are easy to handle wooden girders made from pine wood. It is light in weight and very easy to handle. We can supply in various sizes up to 12 meters in length. Glue used – WBP |

Adjustable Telescopic Spans are the most versatile and widely used system to support slab formwork. The span length is adjusted to the required length and both the ends are supported by means of adjustable props / standards and the space between these spans can be filled by using steel or timber plank to cast the slab. The spans are manufactured in various lengths.

|